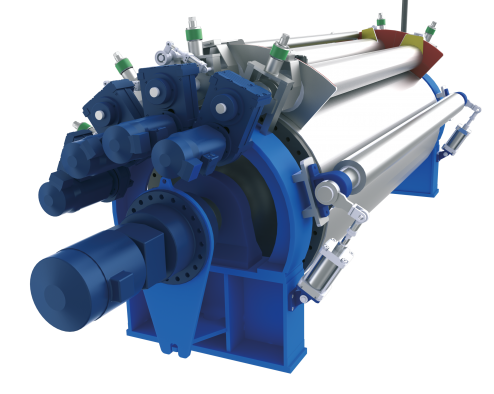

Single Drum

Precision-engineered for the specific dehydration needs of Cereal/Starch/Fruit and many more mixes, our Drum Dryer with Applicator Rolls represents the best of the best in drying technology. This machine is known for an optimized the drying process with high efficiency and superior results.

The process starts as the product enters the gap (or first bath) between the first applicator roll and either a contra-rotating roll or a plate. Here, it is contained between the nip of the main roll and the first applicator roll, creating a thin, uniform film on the main drying roll.

Efficient removal of excess product from the first applicator roll is achieved through a scraper, forming an additional layer of material—a ‘sausage’—between the first and second applicator rolls. This secondary layer undergoes a repetition of the process as it is drawn into the nip of the main roll and the second applicator roll, keeping and improving the thickness on the main drum. Multiple applicator rolls further improve this thickness, ensuring a controlled and efficient drying cycle.

As the drum rotates, moisture is evaporated from the product film, resulting in dried product. The final touch is the removal of the dried product by a precision (doctor) knife, completing the cycle with finesse.

Experience the best of dehydration technology with our Drum Dryer with Applicator Rolls – where innovation meets performance for unparalleled results.