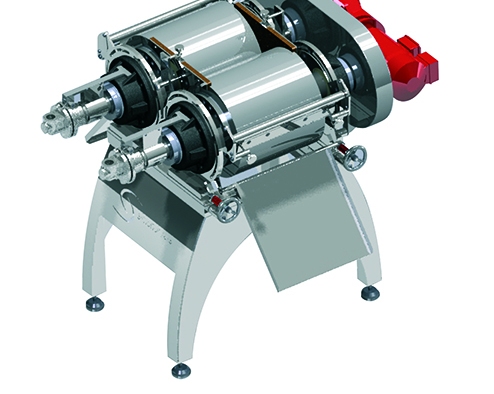

Drum Flaker

Drum Flakers represent as a tool for transforming materials from a molten or liquid state into conveniently manageable solid flakes through a single-step process. This technology involves applying molten products onto the surface of a cooled, rotating drum, where they undergo a solidification process as the drum continues to rotate.

Various feed methods, such as dip feed trays, applicator rolls, and top feed boxes, or a strategic combination of these, cater to diverse operational needs. This adaptability ensures that the Drum Flaker is versatile enough to accommodate different materials and processing requirements.

Primarily recognized for its’ competence in the production of flaked polyethylene glycols (PEGs), waxes, fatty acids, and similar substances, Drum Flakers offer a comprehensive solution for a range of industries. The technology not only streamlines the conversion process but also guarantees a reliable and consistent output of solid flakes, improving efficiency and precision in the manufacturing of these critical materials.

The bottom line is, Drum Flakers demonstrate a practical and versatile approach to solidifying molten products, providing a robust and dependable solution for industries dealing with a spectrum of materials, from PEGs to waxes and fatty acids.