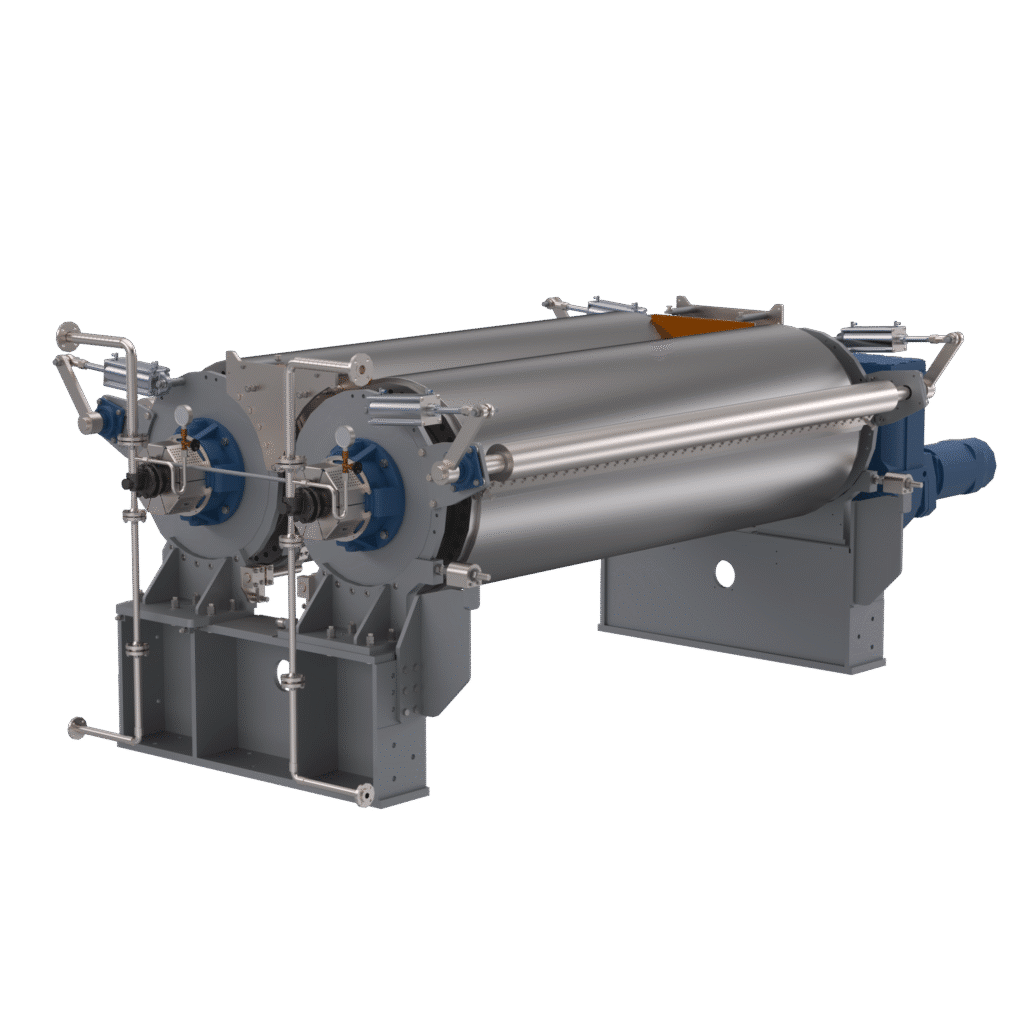

Why choose the Double Drum?

-

Proven reliability Over a century of expertise in drum drying technology.

-

Versatile applications Handles liquids, slurries, and free-flowing materials with ease.

-

High thermal efficiency Steam-to-evaporation ratios as low as 1.2:1, minimizing energy use.

-

Consistent results Adjustable drum gap for precise film thickness and moisture control.

-

Durable construction Heavy-duty cast iron or carbon steel drums for long service life.

-

Flakes or powder output Adaptable for both end-product formats.

Talk to our drying specialists and we’ll help you design the best setup for your product.

How it works

The Double Drum Dryer operates with two steam-heated drums rotating in opposite directions.

Liquid product is fed into the nip between the drums, where the film thickness can be precisely adjusted by changing the drum gap.

As the drums rotate, moisture evaporates rapidly from both sides of the thin film.

Two doctor knives remove the dried product from the drum surfaces, which is then cooled, broken into flakes or powder, and collected via conveyors.

Optional air knives, take-off rollers, and vapour extraction systems improve cooling, hygiene, and workplace safety.

Applications

- Dairy products – milk powders, baby food bases

- Fruits & vegetables – banana, tomato, etc

- Breweries – drying spent yeast and other by-products

- Pet food – drying slurries into flakes or powder

- Algae & seaweed – nutrient-preserving dehydration

- Proteins & biologicals – drying sensitive organic materials

Not sure if your product fits?

Use our laboratory testing facilities to analyze drying behavior, energy efficiency, and final product texture.

Built for performance

The Double Drum Dryer combines simplicity, robustness, and efficiency, making it a true industry workhorse.

With over 100 years of proven performance, it remains one of the most energy-efficient and versatile dryers on the market.

Why work with us?

100+ years

Experience in drying technology.

Engineered

Machines designed for dust control, energy efficiency, hygiene and clean-label compatibility.

Support

From testing in our lab to installation and after-sales service.

Sustainable

Efficient steam use, minimal waste and high product yield.

Frequently asked questions

The Double Drum Dryer handles liquids, slurries, and suspensions, including milk, yeast, fruit and vegetable pulps, pet food, algae, and seaweed.

It achieves steam-to-evaporation ratios as low as 1.2:1, meaning more water removed per unit of steam.

Pre-concentrating feed liquids further reduces energy demand and allows for smaller dryer sizes.

Yes. Air knives and film take-off rollers can be added to cool and remove high-sugar or viscous materials efficiently.

The Double Drum Dryer is ideal for thinner product films and higher throughput of liquid materials.

It provides faster drying and greater uniformity when processing free-flowing liquids.

Absolutely. Our lab and pilot dryers are available to test your product and optimize parameters before full-scale installation.

It’s designed for low maintenance and high reliability, with heavy-duty bearings, safety guards, and automatic knife control.

Yes. The design supports hygienic operation, optional stainless-steel finishes, and vapour extraction systems for clean, safe drying.