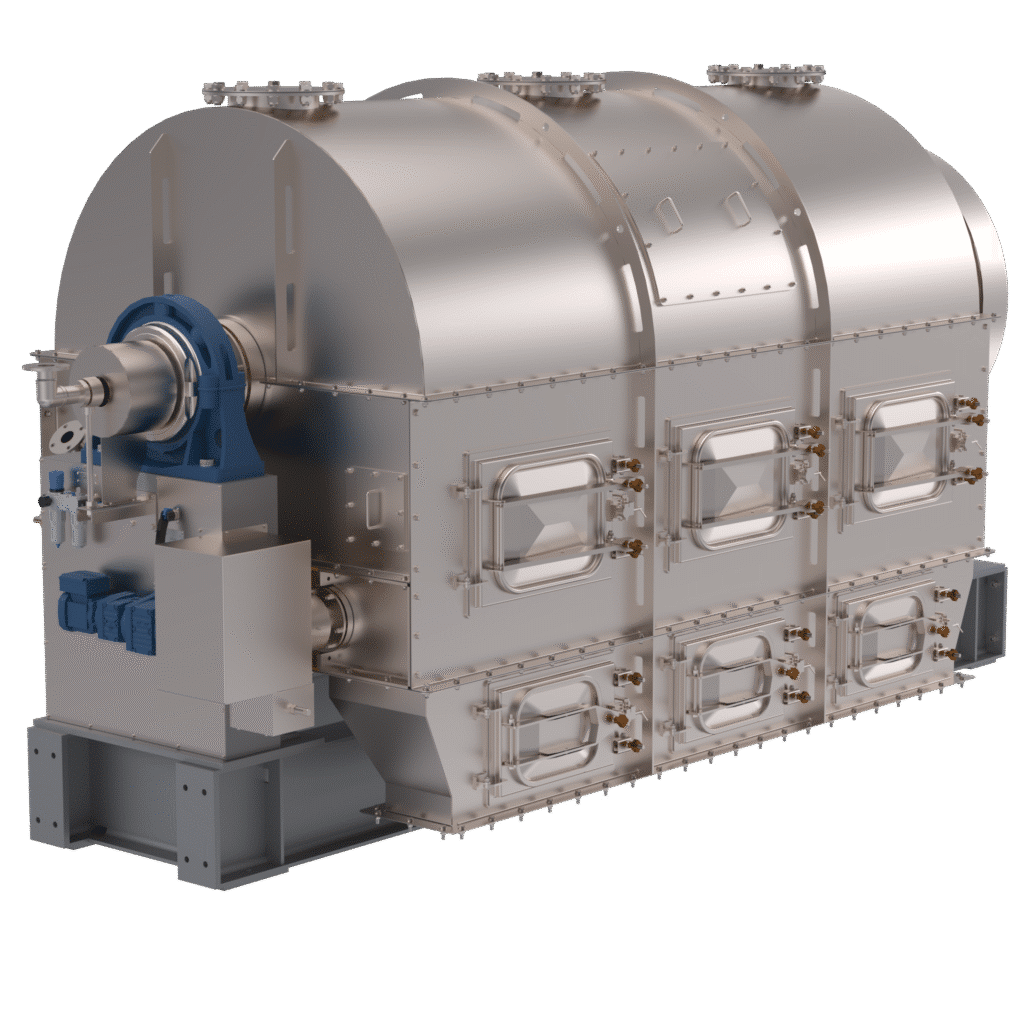

Why choose the Drum Flaker?

-

Single-step process Transforms molten or liquid feed into solid flakes directly.

-

Energy-efficient & compact Water- or Glycol-cooled drum for continuous, stable operation.

-

Safe & controlled Enclosed design minimizes operator exposure and heat hazards.

-

Custom-built Available in carbon steel, stainless steel, cast iron, or alloy steels for full material compatibility.

-

Easy to operate & maintain Simple setup, quick cleaning, and long service life.

-

Proven across industries Trusted for over a century in food and non-food processing.

Find the right flaking setup for your product.

How it works

The Drum Flaker applies a thin film of molten material onto the outer surface of a horizontally rotating drum, internally cooled by water, brine, or other coolants.

As the drum turns, the film solidifies into a uniform sheet, which is then safely removed by a doctor knife, producing solid flakes ready for packaging or further processing.

Different feed systems, such as dip trays, applicator rolls, or top feeders, ensure compatibility with a wide range of viscosities and product types.

Applications

The Tummers Simon Dryers Drum Flaker is used to produce solid flakes from materials with melting points ranging from ambient to over 300°C, including:

- Waxes and fatty acids

- PEGs (polyethylene glycols)

- Resins and soaps

- Detergents and surfactants

- Chemical intermediates

- Pharmaceutical compounds

- Food ingredients and additives

Not sure if your material can be flaked?

Our laboratory flakers are available for testing under controlled conditions.

Safety and design

The Drum Flaker is designed with operator safety and process control at its core:

- Enclosed cooling system prevents leaks or splashes of hot materials.

- Optional dust- and fume-tight housings for hazardous or reactive products.

- Temperature-controlled drum maintains consistent flake thickness and quality.

- Emergency safety stops and guarding around moving parts ensure reliable, safe operation.

- Low-noise drive units and ergonomic design for a comfortable working environment.

Why work with us?

100+ years

Experience in drying technology.

Engineered

Machines designed for dust control, energy efficiency, hygiene and clean-label compatibility.

Support

From testing in our lab to installation and after-sales service.

Sustainable

Efficient steam use, minimal waste and high product yield.

Frequently asked questions

It handles organic and inorganic materials with melting points up to 300°C, such as PEGs, waxes, fatty acids, soaps, and resins.

It’s also suitable for pharmaceuticals, chemicals, and food additives.

Standard options include water, brine, or specialized coolants, depending on the material’s melting temperature and heat sensitivity.

Yes — it features closed cooling circuits, mechanical guarding, and pneumatic knife control for consistent and safe performance.

Absolutely. Drums can be built in carbon steel, stainless steel, or alloy steels to match your product’s chemical and thermal properties.

Depending on viscosity and behavior, we use dip trays, applicator rolls, or top feeds for precise film control.

Yes — our pilot and laboratory flakers are available for product trials and parameter optimization.

That depends on the feed system, drum speed, and temperature control.

Our engineers can help you tailor the setup to your desired flake characteristics.