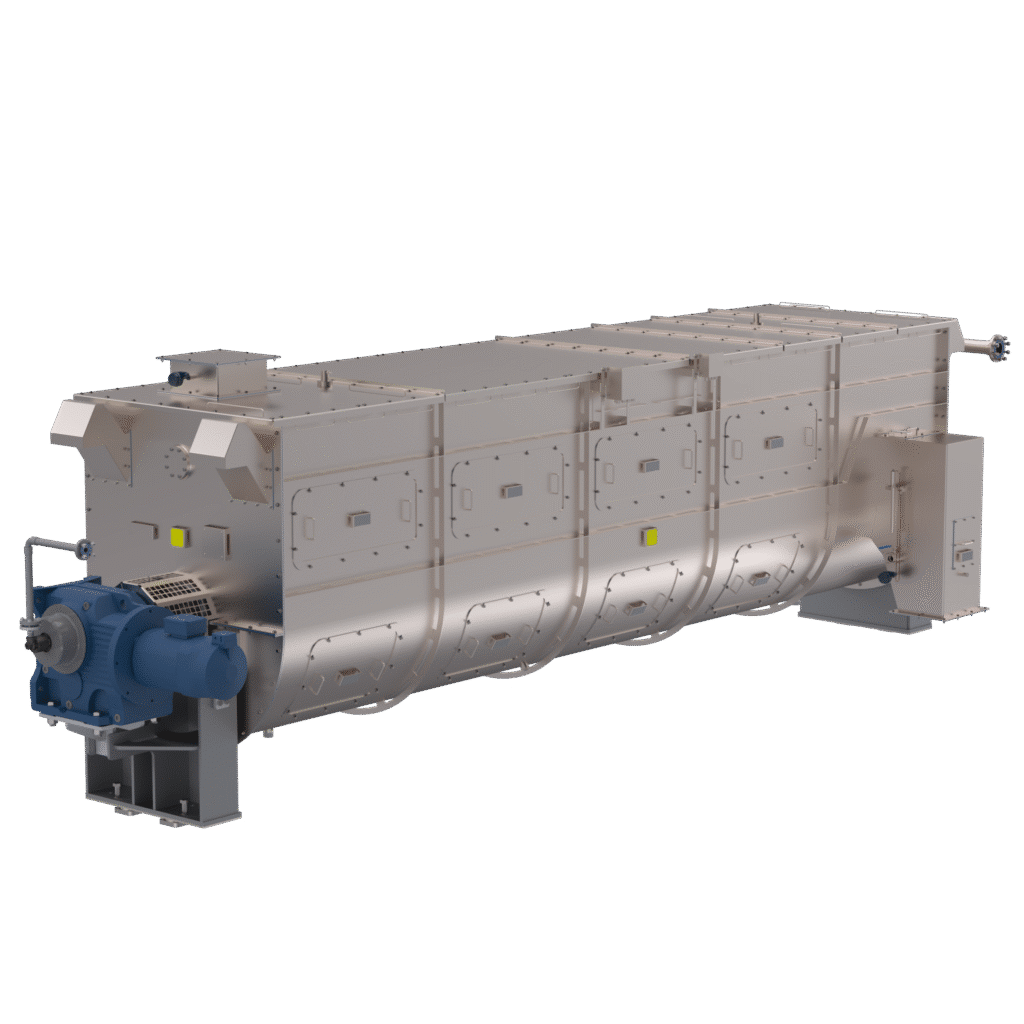

Why choose the Tubular Dryer?

-

Continuous operation Reliable drying and conditioning 24/7

-

Energy-efficient Uses dry, saturated steam with condensate return to the boiler for optimal heat recovery.

-

Low dust, high safety Minimal sweep-air, smaller filters, and reduced dust explosion risks.

-

Compact & easy to maintain Fewer moving parts and simple cleaning.

-

Seamless integration with Tubular Cooler Perfect control of moisture and temperature.

Let’s talk about your process — our specialists are ready to help.

How it works

The Tubular Dryer operates with a steam-heated tube bundle rotating inside a stationary casing.

A series of lifters pick up the material and cascade it over the heated tubes while it’s conveyed along the length of the machine.

- The steam inside the tubes provides indirect heat for drying.

- A small amount of sweep air removes the evaporated moisture.

- Rotary joints at each end handle steam inlet and condensate collection.

Once dried, the powder exits the dryer at an elevated temperature and is fed directly into the Tubular Cooler, which uses water as a coolant.

Together, they form an efficient, closed, and energy-recovering drying system.

Applications

- Confectionery – conditioning and drying of moulding starch

- Maize milling – drying maize germ and gluten meal

- Breakfast cereals – pre-heating and moisture control of cereal grains

- Metal powders – safe, controlled drying with minimal dust

- Pharmaceutical – drying a range of powders and granulates

Not sure if your product fits?

Use our laboratory; we can test your material, analyze drying curves, and recommend the best configuration.

Better than a Belt Dryer or Fluid Bed Dryer

The Tubular Dryer is an indirect-contact dryer using dry saturated steam instead of hot air, providing significant safety and efficiency advantages:

- Lower dust explosion risk due to minimal air flow

- Smaller dust filters, reducing operating cost and maintenance

- Closed system with minimal contamination and consistent product quality

- Condensate recovery returning steam condensate to the boiler for energy reuse

- Uniform drying through precise control of temperature and residence time

Optional module: Tubular Cooler

Often paired with the dryer, the Tubular Cooler is installed directly beneath or alongside it — ensuring smooth transfer and precise control of final temperature and moisture.

Ideal for moulding starch and other heat-sensitive materials.

100+ years

Experience in drying technology.

Engineered

Machines designed for dust control, energy efficiency, hygiene and clean-label compatibility.

Support

From testing in our lab to installation and after-sales service.

Sustainable

Efficient steam use, minimal waste and high product yield.

Frequently asked questions

Absolutely. The indirect drying design minimizes dust formation and product carryover.

Yes. We translate lab data into predictable pilot and full-scale performance.

A steam supply, condensate return, and limited sweep air. We can help define the specs for your setup.