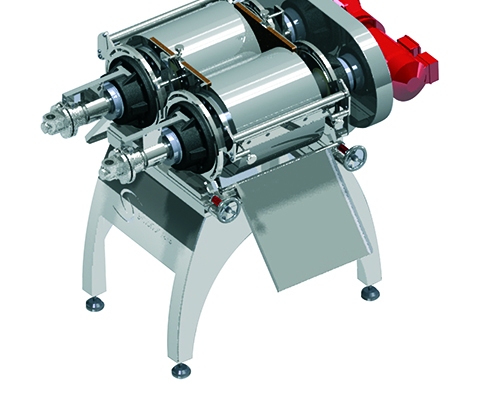

The laboratory Drum Dryer is designed for food, chemical and pharmaceutical research.

The unit can be used for product development and educational use, ideally demonstrating the many drum drying and flaking applications to students. The equipment is supplied fully assembled and ready for connection to site services. Conversion to flaking operation can be achieved within minutes.

Construction

The design is fully interchangeable so that any configuration can be achieved by fitting the relevant accessory. The unit is constructed from stainless steel, providing cleanliness and resistance to chemical attack. The drums are cast iron and engineering hard chrome plated to ensure maximum heat transfer and the ability to scale up results to production sized equipment. The shaft mounted main drive speed is simply adjusted by electronic inverter in the control panel.

Optional Accessories

Vapour Extraction System

This is fitted above the dryer and draws the vapours produced when drying away through the fan and duct assembly.

Feed System

The stainless steel feed tank and variable speed pump deliver the material to be dried through the solid pipeline to the dryer feed.

Applicator Roll

The applicator roll can be used on both drying and flaking applications, and gives extra control for those materials requiring it.

Feed Roll Assembly

The double drum dryer can be easily converted to operate as a single cylinder feed roll drum dryer with this accessory.

Dip Tray

The dip tray is positioned under the drum and is used to simply apply a film for either drying or flaking purposes.

Specification

Drum size :- 300mm diameter x 300mm long

Shipping dimensions :- 2700mm long x 1500mm wide x 1500mm high

Weight :- Approximately 2500 kg

Drying duty :- Max material feed rate 45 kg/hr ; Max water evaporated 30 kg/hr ; Steam consumption 40 kg/hr @ 6 barg

Flaking duty :- Max material feed rate 150 kg/hr ; Coolant consumption 2500 lt/hr

Feed Systems (click to open)

|